Manufacturing Process

The manufacturing process of a PCB involves several steps, from design to production. The first step is the design of the PCB. The design outlines the different layers of the board and ensures that all the components are placed correctly. Once the design is completed, the manufacturer sends it to the printing press.

The printing press uses a special ink to print the design onto the copper base. The ink used is typically a negative image of the design, so that only the intended areas of the copper base are etched away while the rest remains. This creates the necessary pathways for the electrical currents to flow through the board.

After the ink has been applied, the copper board is coated with a photosensitive layer. This layer is sensitive to light, and the design is then printed onto the photosensitive layer using a special printer. The board is then exposed to UV light, which makes the photosensitive layer harden and adhere to the copper base.

The next step is the etching process. This process involves removing the unwanted copper with a chemical etchant. The etchant eats away at the areas of the copper base that have not been covered by the photosensitive layer, leaving behind only the intended pathways.

Once the etching is complete, the board is cleaned to remove any remaining ink or photosensitive layer. The board is then drilled to create the necessary holes for the components to be added.

Assembly Process

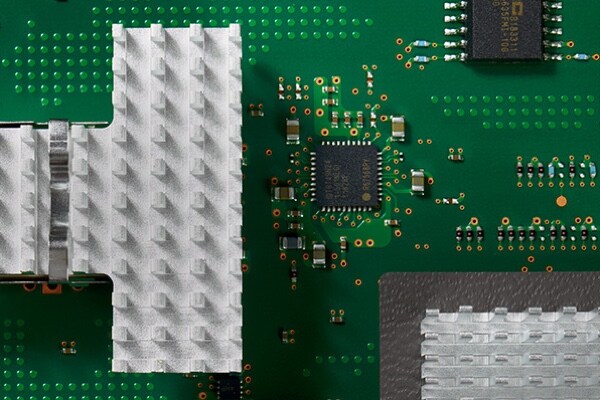

The assembly of the PCB involves adding the components to the board and then connecting them using solder. The components are typically placed on the board by a machine, which ensures that they are placed in the correct locations. The machine then adds solder to the connections, which secures the components in place and creates the necessary electrical connections.

Once the components have been added, the board is inspected to ensure that everything is properly connected and there are no defects. Any defects are then corrected, and the board is tested for functionality.

Vacuum Solutions for PCB Production

Vacuum solutions play a crucial role in the production of PCB. Schmalz, a company specializing in vacuum technology, offers solutions for every process step of PCB production. The vacuum system is used to hold the PCB securely in place during the drilling and assembly processes. It prevents the board from moving during these processes, which could lead to misaligned components and damaged PCBs.

Schmalz also offers customized vacuum systems for specific applications, which ensures that the PCB production process is efficient and effective. By using a vacuum solution from Schmalz, the PCB production process can be streamlined, reducing errors and improving the quality of the final product.

Conclusion

The production of a PCB is a complex process that involves several steps, from design to assembly. By using vacuum solutions from Schmalz, the production process can be made more efficient and effective. Vacuum solutions are essential in ensuring that the PCB remains securely in place and that the components are properly aligned. Overall, by using vacuum solutions, the PCB production process can be streamlined, reducing errors and improving the quality of the final product.