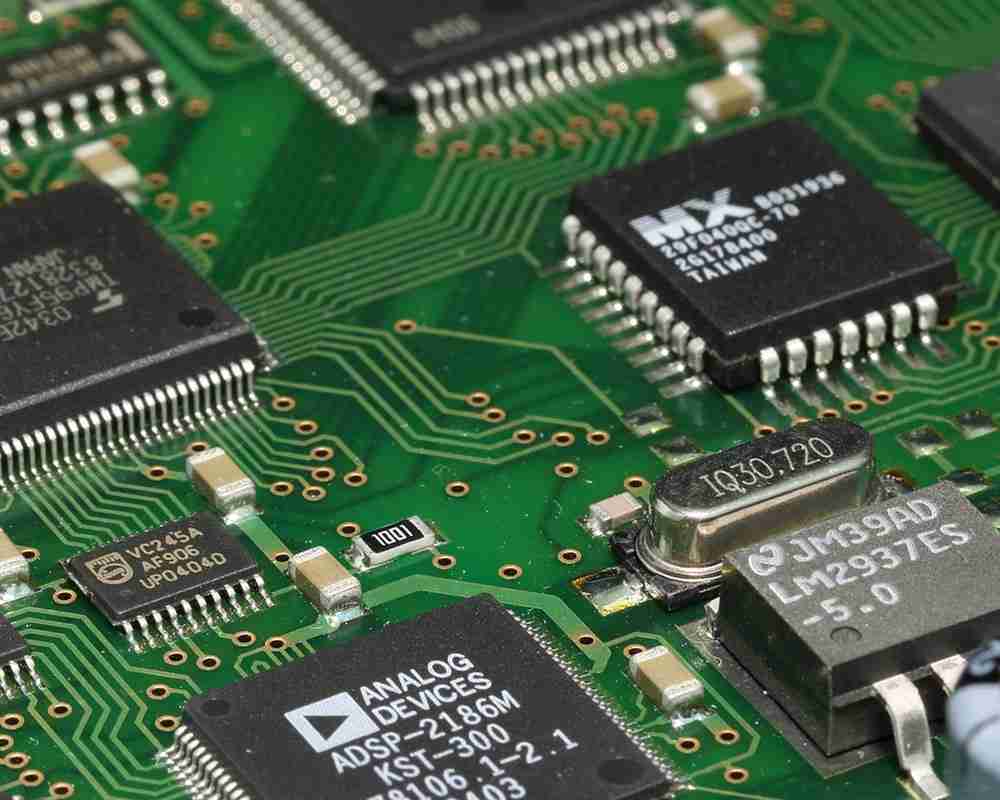

The printed circuit board assembly (PCBA) process is an essential step in the manufacturing of electronic devices. It involves attaching the electronic components to the PCB to create a functional electrical circuit. The process starts with the preparation of the raw printed circuit board. The board is inspected for any faults and then cleaned to remove any dirt, dust, or debris.

The electronic components are then selected based on the circuit design and the specifications of the project. The components are usually small and delicate, and so require careful handling to avoid damage. The ICs, resistors, capacitors, and other components are then placed on the board using automated machinery, known as pick-and-place machines.

The pick-and-place machines are programmed to pick up the components and place them accurately on the board. Once all the components have been placed, a solder paste is applied to the board. The solder paste is a mixture of flux and small balls of solder. The flux helps to clean the area around the component, while the solder balls melt and form a bond between the component and the board.

The board is then placed in a reflow oven, where it is heated to a temperature of around 250 degrees Celsius. This causes the solder paste to melt and the components to be soldered to the board. Once the board has cooled down, it is inspected for any defects or faults. Any defects are identified and corrected before moving on to the next stage.

The next stage is the testing of the finished PCB. The testing involves applying a series of electrical tests to the PCB to ensure that it is functioning correctly. The PCB is tested for circuit continuity, voltage, and resistance. Any issues identified during testing are addressed before the PCBs are shipped to customers.

Minewing, a company specializing in concept realization and electronics customization, has extensive experience in the PCBA process. They have a team of experts who ensure that the PCBA process is carried out efficiently and effectively. They work closely with their customers to ensure that the PCBs meet their specifications and requirements.

Minewing understands the importance of seamless cooperation between the teams. They work closely with their customers to ensure that the PCBA process is carried out as smoothly as possible. They offer complete project management services, from concept design to final product assembly, to ensure that the entire process is well coordinated and the end product is of high quality.

In conclusion, the PCBA process is an essential step in the manufacturing of electronic devices. It requires careful handling of delicate components and thorough testing to ensure that the finished product is of high quality. Companies such as Minewing have extensive experience in the PCBA process and can offer complete project management services to ensure that the entire process is well-coordinated and the end product meets customer specifications and requirements.